Nanocluster Deposition

Home / JVD™ Technology / Nanocluster Deposition

Nanocluster Deposition

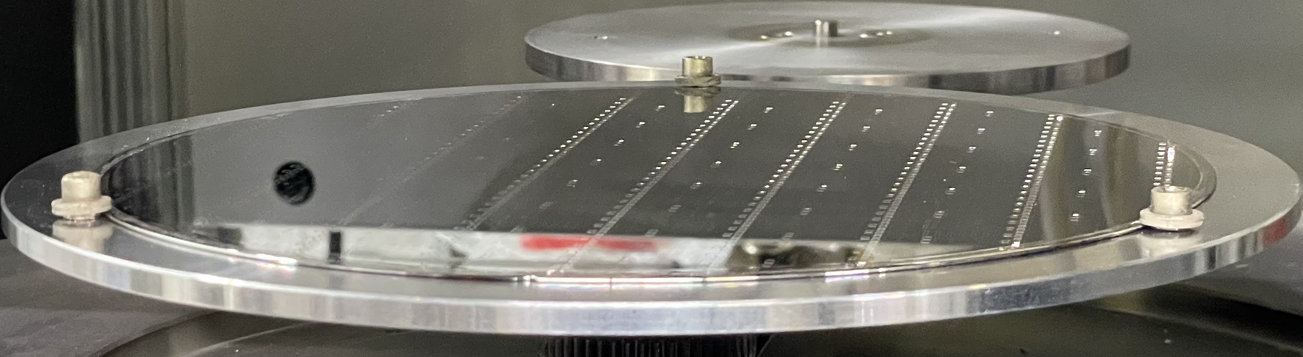

JVD flow and pressure conditions can be easily modified in the nozzle and jet to promote high rate nucleation, growth, and deposition of nanoclusters. The key advantage is that cluster deposition is far more directional than atom deposition. Once the heavier nanocluster has been accelerated, its high inertia constrains its trajectory to be almost exactly perpendicular to the wafer. In consequence, there is little shadowing by resist walls, and since sidewall deposition is also reduced, there is

reduced breadloafing. For small windows in the photoresist, where the aspect ratio is high, hole filling by nanoclusters is far more efficient than filling with atoms. We have been putting this key nanocluster capability of JVD to increasing use in making small solder bumps in dense arrays. For example, with nanocluster AuSn, we have deposited arrays of solder bumps 4 microns in diameter with a pitch of 8 microns.

Nanocluster deposition is a modified operating mode. The clusters deposit in a collimated fashion nearly perpendicular to the substrate, making it well suited for jobs with very small features or those with high aspect ratios. The result is a well defined feature with no shadowing or distortion. It also has the benefit of supporting an easier and cleaner liftoff.

Ask us if nanocluster deposition is right for your job.

For more information on our clean and green nanoclusters, please click below for the 2011 EPA SBIR success story in “Science Matters”. https://www.epa.gov/sites/default/files/2015-06/documents/jetprocess.pdf