Jet Vapor Deposition

Home /About Us / Jet Vapor Deposition

Jet Vapor Deposition™ (JVD™)

JVD’s low temperature, low vacuum operating conditions are compatible with photoresist patterns, most heat sensitive mask materials and substrates, sometimes including materials that outgas.

JVD offers many advantages over conventional techniques such as sputtering, evaporation, CVD and electroplating, and has demonstrated its versatility in a wide variety of contract R&D and production work. JVD is an economical, safe, clean and environmentally sound process that is free from toxic effluents.

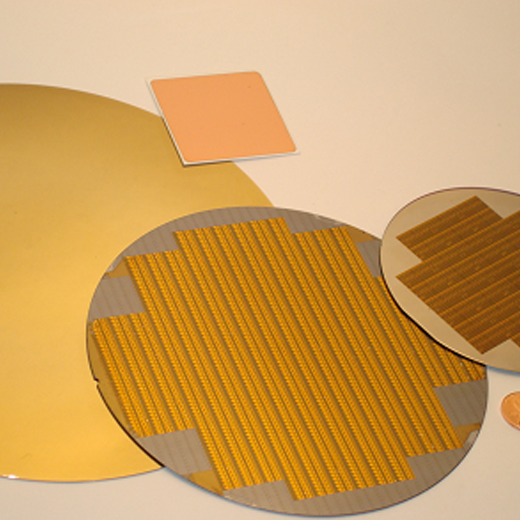

We can handle a variety of substrate types and sizes, up to 8 inch wafers. Our coating capabilities are ideal for a UBM stack or a sequence of up to 4 different source materials in the same run, under the same vacuum.

Why JVD ?

Thin Film Expertise

We are the thin film deposition experts with decades of experience. We provide high quality, precision thin films exclusively. As devices get smaller, faster and more demanding, we meet today’s new thin film coating challenges. We replace older solder technologies such as preforms, solder paste and electroplating with a high quality alternative thin film solution.

We work with the customer to develop a custom solution for their job.

Major Process Advantages

- Low temperature, low vacuum deposition of a wide range of solders and adhesion/barrier metals

- Photoresist compatible

- Batch processing in some cases

- Reliable thickness control

- Wide range of substrate types and geometries

- Clean, green technology

Quality

Jet Process sources only the highest quality deposition materials to exacting standards from trusted suppliers. Standard metal purity is a minimum of 99.99%. Every lot is analyzed and certified for metal content and purity. Alloy compositions are guaranteed to be within tight tolerances.

Outstanding Service

In addition to our numerous advantages versus conventional deposition techniques, we offer outstanding, second-to-none personal service. We are customer focused. We work with you to find the appropriate solution for your individual coating needs. We serve the volume production customer as well as the prototype and R&D customer.

Fast Turnaround

We understand that solder is one step in the complex manufacture of your wafers and devices, and that time is of the essence. We make every effort to fit into your production schedule so that you can meet your product and customer needs to satisfy market demand.

White Glove Handling

Our white gloves are made of nitrile. We understand that you have a great deal invested in your devices, which is why we treat your parts as if they were ours. All customer parts are handled only by qualified, trained personnel following strict handling procedures. From receiving to storage to coating to shipping, we do everything we can to ensure proper handling, storage and a safe round trip.